QM-DIAL

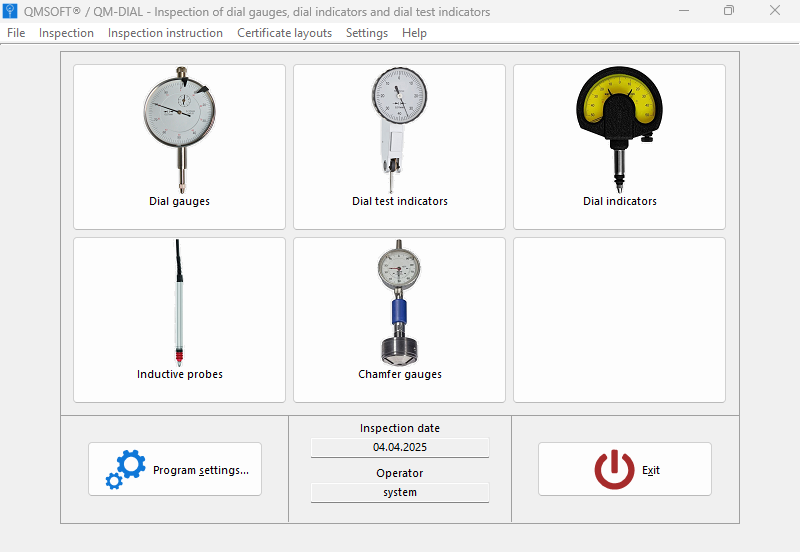

The QMSOFT®/QM-DIAL program is used for the computer-aided testing of dial indicators, precision indicators and lever gauges. In addition to testing according to the relevant DIN standards, the program enables testing based on the corresponding Australian, British, French, Korean, Japanese and US standards.

Description

The QMSOFT®/QM-DIAL program is used for the computer-aided testing of dial indicators, precision indicators and lever gauges. In addition to testing according to the relevant DIN standards, the program enables testing based on the corresponding Australian, British, French, Korean, Japanese and US standards. The following national standards are currently implemented in the program:

- Dial indicators according to DIN 878

- Finish pointer according to DIN 879

- Feeler gauges according to DIN 2270

- Dial indicators according to US standard ASME/ANSI B89.1.10M

- Dial indicators according to “British Standard” BS 907-1965

- Feeler gauges according to “British Standard” BS 2795-1981

- Dial indicators and lever gauges according to Australian Standard AS 2103

- Dial indicators according to Korean standard KS B 5206-1984 and KS B 5207-1984

- Feeler gauges according to Korean standard KS B 5238-1976

- Dial indicators according to “Japanese industrial Standard” JIS B 7503-1992

- Dial indicators according to “Norme francais” NF E 011-50

- Feeler gauges according to the French standard XP E 11-053

Dial indicators, precision indicators or lever gauges can be tested according to various testing strategies, i.e. with reference to the testing regulations of the associated national standard, according to the VDI/VDE/DGQ guideline 2618 (sheets 11.1, 11.2 and 11.3), according to the DKD guideline DKD-R 4 -3 or tested according to freely defined factory guidelines.

For the test items, depending on the selected test strategy and standard, the program determines from the measurement data the deviation range fe, the deviation range ft in the partial measuring range, the total deviation range ftot, the repeatability fw and the measurement reversal range fu (or, in the case of precision indicators, the corresponding measurement deviations). For the testing of precision indicators according to DIN 879, the measurement deviations defined there are calculated. The input parameters required for the evaluation are checked for plausibility in accordance with the scope of the applicable standard or guideline.

Knowledge of the standards and mastery of the measuring methods used for gauge testing are required. The measurement data can be entered either from a measuring device linked online or via a keyboard. In the result log, the master data of the test item is clearly prepared in conjunction with the test conditions and the measurement results. Tolerance violations are marked and reported in terms of amount.

The program works with the test equipment management programQMSOFT®/QM-MANAGE professional edition, whereby the The test results obtained by the program (including the test report) are then returned directly to the test equipment database.

Screenshots