QM-PLAIN

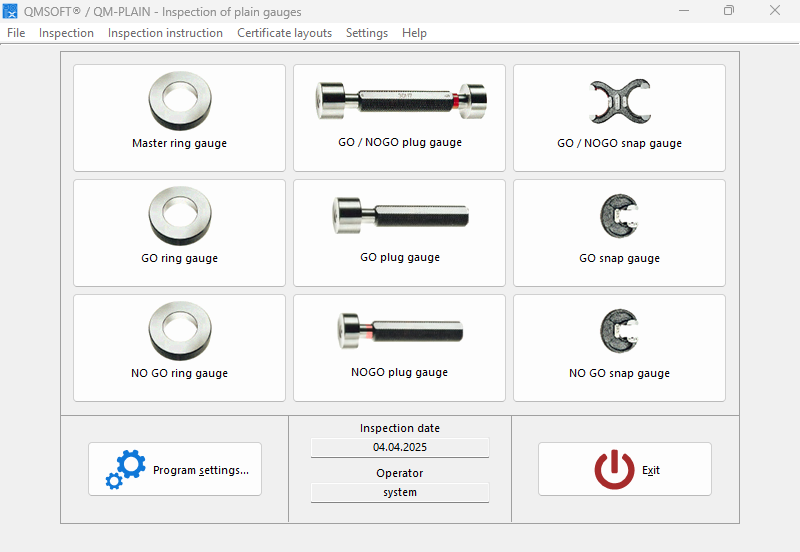

The QMSOFT®/QM-PLAIN program is used for the computer-aided testing of smooth gauges, i.e. good, no-go and limit mandrel gauges, go-good, no-good and limit jaw gauges, good and no-go ring gauges as well as setting rings.

Description

The QMSOFT®/QM-PLAIN program is used for the computer-aided testing of smooth gauges, i.e. good, no-go and limit mandrel gauges, go-good, no-good and limit jaw gauges, good and no-go ring gauges as well as setting rings. For all supported gauges, the calculation of the nominal workpiece dimensions and gauge dimensions is implemented according to the following standards:

- Good ring gauges according to DIN 7150-2:2007, BS 269:1982, ANSI/ASME B89.1.6M, NF E 02-202

- Reject ring gauges according to DIN 7150-2:2007, BS 269:1982, ANSI/ASME B89.1.6M, NF E 02-202

- Setting rings according to DIN 2250-1 October 2008, BS 4064, BS 4065,

- ANSI/ASME B89.1.6M, NF E 11-011

- Good plug gauges according to DIN 7150-2:2007, BS 269:1982, ANSI/ASME B89.1.6M, NF E 02-202

- Reject plug gauges according to DIN 7150-2:2007, BS 269:1982, ANSI/ASME B89.1.6M, NF E 02-202

- Limit plug gauges according to DIN 7150-2:2007, BS 269:1982, ANSI/ASME B89.1.6M, NF E 02-202

- Good jaw gauge according to DIN 7150-2:2007

- Reject jaw gauge according to DIN 7150-2:2007

- Limit jaw gauge according to DIN 7150-2:2007

- Measurements with spherical end faces according to DIN 7150-2:2007

- Test gauges for jaw gauges according to DIN 7150-2:2007

- Shipping washers type 1, 2 and 3 according to ANSI/ASME B89.1.6M

At the touch of a button, the program calculates the nominal dimensions and gauge dimensions from the target dimension name of the gauge to be entered (e.g. 20 H7 or 20 +0 -21) and the gauge type (ring, mandrel, jaw gauge). Limitations of the underlying standards are noted. Furthermore, all dimensions can be freely entered, so that even the most unusual gauge dimensions do not pose a problem. It is also possible to save and use user-specific factory standard tolerances.

The test itself is carried out in accordance with the VDI/VDE/DGQ guideline 2618 (sheet 4.1 and sheet 4.7). Knowledge of this guideline and mastery of the measuring procedures used for gage testing are required. The measurement data can be entered either from a measuring device linked online or via a keyboard. In the result log, the master data of the teaching is clearly prepared in conjunction with the test conditions and the measurement results. Tolerance violations are marked and reported in terms of amount.

The program works with the test equipment management program QMSOFT®/QM-MANAGE professional edition, whereby the The test results obtained by the program (including the test report) are then returned directly to the test equipment database.

Screenshots