QM-TAPERTHREAD

Description

The QMSOFT®/QM-TAPERTHREAD program is used for the computer-aided testing of tapered pipe threads or gauges for testing tapered pipe threads. The generation of all required thread (gauge) target values and tolerances for the following standards is supported:

- Pipe Threads, General purpose (NPT..) according to ANSI/ASME B1.20.1 – 1983

- Pipe threads where pressure-tight joints are made on the threads according to ISO 7-2:2000

- Pipe threads for tubes and fittings according to BS21:1985

- Metric External Taper Screw Threads according to DIN 158

- Gauges for Dryseal Pipe Threads (e.g. NPTF..) according to ASME B1.20.5-1991

- Whitworth Pipe threads for threaded pipes and fittings according to DIN 2999 – July 1983

Attention: The measuring procedure for calibrating tapered threads (gauges) requires special measuring device accessories. In the event that the flank diameter is defined in a special reference plane, a second coordinate axis is required on the length measuring device: the main axis is used to measure the flank diameter, the minor axis is used to determine the distance to the reference surface.

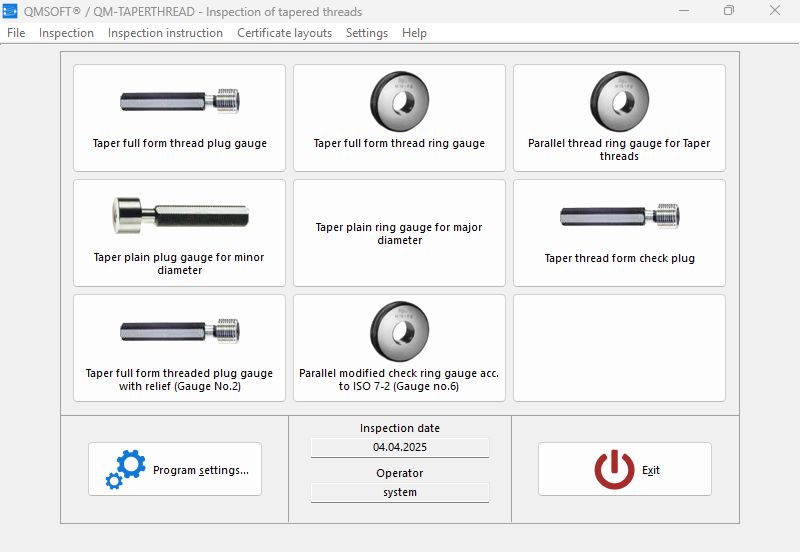

After selecting the gauge type (e.g. tapered thread gauge ring) and entering the thread designation (e.g. R1), the program QMSOFT®/QM-TAPERTHREAD calculates all the required gauge dimensions and tolerances for all standardized types of tapered thread gauges or for all types of smooth ones at the push of a button Gauges used to check the smallest and largest diameters of tapered thread gauges. Limitations of the underlying standards are noted.

Knowledge of the standards and mastery of the measuring methods used for gauge testing are required. The measurement data can be entered either from a measuring device linked online or via a keyboard. In the result log, the master data of the test item is clearly prepared in conjunction with the test conditions and the measurement results. Tolerance violations are marked and reported in terms of amount.

The program works with the test equipment management program QMSOFT®/QM-MANAGE professional edition, whereby the The test results obtained by the program (including the test report) are then returned directly to the test equipment database.

Screenshots