QM-PIN

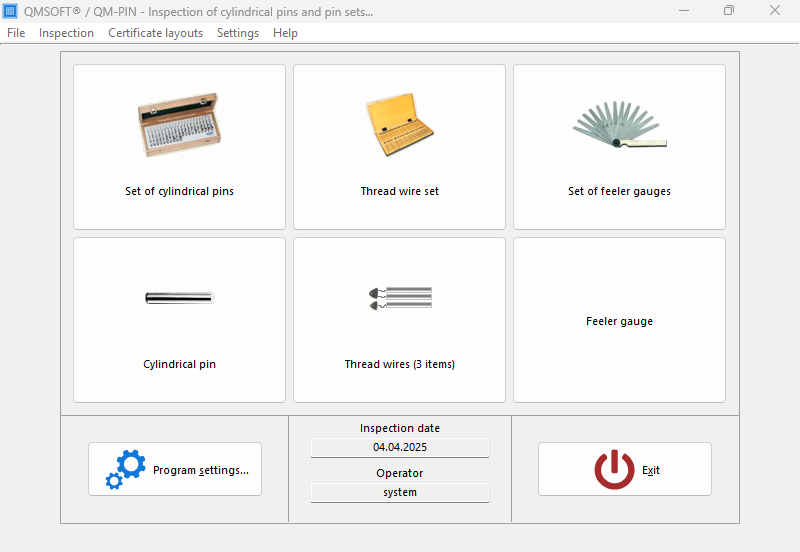

The QMSOFT®/QM-PIN program is used for the computer-aided testing of cylindrical test pins (both as a single test pin and as a test pin box) as well as thread measuring wires, such as those used for thread measurement using the three-wire method. In addition, it is also possible to test other test equipment where a series of graduated length or thickness measurements have to be tested (such as feeler gauge sets).

Description

The QMSOFT®/QM-PIN program is used for the computer-aided testing of cylindrical test pins (both as a single test pin and as a test pin box) as well as thread measuring wires, such as those used for thread measurement using the three-wire method. In addition, it is also possible to test other test equipment where a series of graduated length or thickness measurements have to be tested (such as feeler gauge sets).

Depending on the manufacturer, a complete set of thread measuring wires or test pins consists of a certain number of wires or pins with a corresponding diameter rating. When measuring test pins, the program determines the average values as well as the smallest and largest dimensions of the actual diameters of the test pins/measuring wires from the measurement data. The test evaluation is based on the DIN 2269 standard. An evaluation according to factory standards is possible after entering your own tolerance limits. Both dimension-independent tolerance limits and tolerances that are calculated depending on the respective nominal dimension are possible. The measurement data can be entered either from a measuring device linked online or via a keyboard.

QMSOFT®/QM-PIN accesses the test equipment management system QMSOFT®/QM-MANAGE</ for management functions for test pin sets. a> (professional or lite edition), i.e. the storage of the sentence structure, the monitoring of the calibration dates and the storage of the history of a test pen box with all individual measured values and the test certificate can only be found in the module QMSOFT®/QM-MANAGE instead.

Knowledge of the standards and mastery of the measurement procedures used for the test are required. In the result log, the master data of the test item is clearly prepared in conjunction with the test conditions and the measurement results. Tolerance violations are marked and reported in terms of amount.

Screenshots